What is FEA?

Finite Element Analysis is a computational method used by engineers to predict how a product will react to real-world forces, such as heat, vibration, and stress. Think of it as a virtual stress-testing simulator.

The Core Concept: Breaking Down the Complex-:

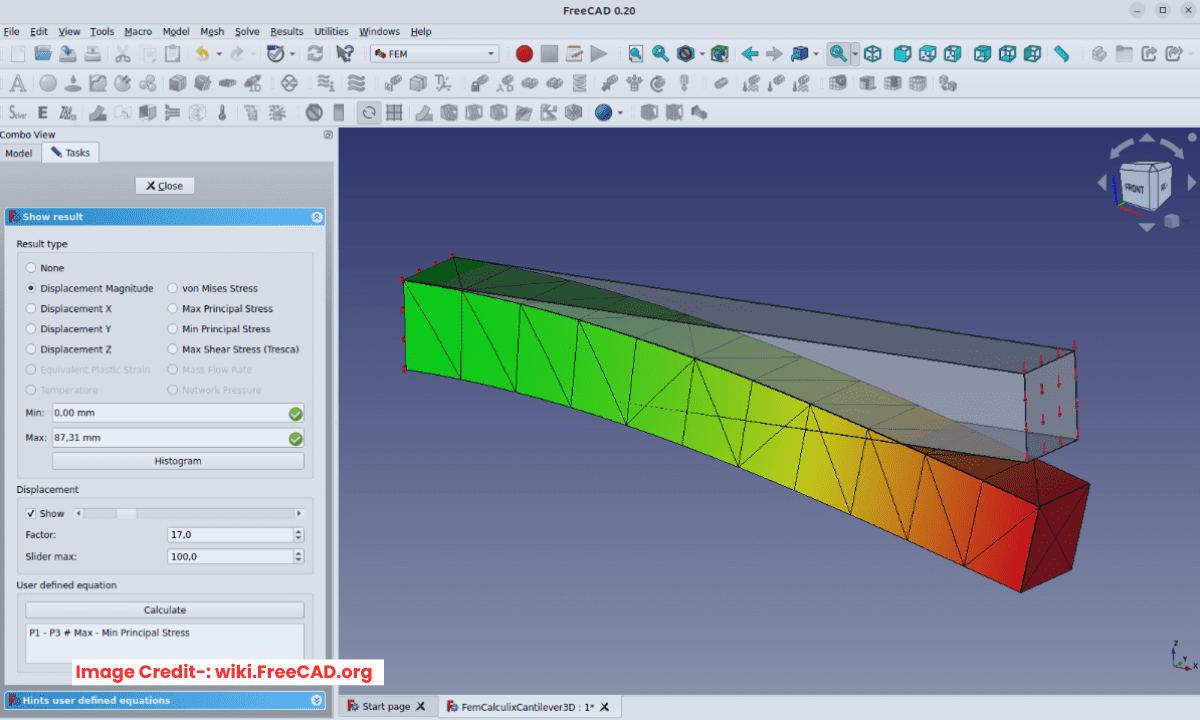

The core idea is simple: you take a complex geometry and break it down into a finite number of small, simple pieces (called “elements”). These elements are connected at specific points (“nodes”). It’s much easier to solve the physics for these simple pieces and then combine the results to understand the behavior of the entire, complex object. This mesh of elements and nodes is called a “mesh.”

A Simple Analogy:

Imagine predicting the sag of a fishing net. Analyzing the entire net at once is difficult. But if you analyze the force on each small knot (node) and the stretch of each piece of string (element), you can assemble the data to see how the entire net deforms. FEA does this for solid objects.

The Basic FEA Workflow:

Pre-Processing (The Setup):

Geometry: You create or import a 3D model of your part.

Meshing: You divide the model into the small elements, creating the mesh. A finer mesh in critical areas gives more accurate results but takes longer to compute.

Material Properties: You define what the part is made of (e.g., steel, aluminum, plastic) by assigning properties like density and strength.

Boundaries & Loads: You apply the real-world conditions: How is it held? (e.g., a bolt hole is fixed). What forces are acting on it? (e.g., a 100 lb weight).

Solving (The Black Box):

The FEA software (like ANSYS, Abaqus, or SimScale) assembles and solves a gigantic set of mathematical equations for every single node. This is the number-crunching phase, handled by the computer.

Post-Processing (The Results):

You visualize the results using color-coded plots. Common results include:

Stress: Where is the part most likely to fail?

Strain: How much is it stretching or compressing?

Displacement: How much does it bend or move from its original shape?

Why Use FEA?

Reduce Physical Prototyping: Test and refine designs digitally, saving immense time and cost.

Identify Weak Spots: Find problem areas before manufacturing.

Optimize Designs: Make parts lighter, stronger, and more efficient.

A Word of Caution for Beginners:

FEA is a powerful tool, but it follows the principle of “Garbage In, Garbage Out.” A beautiful color plot is meaningless if the initial setup (loads, constraints, material) is wrong. Understanding the underlying physics is crucial to interpreting results correctly. Start with simple models and validate your results with hand calculations or known data.

“Thank you for reading! If you found this article insightful and valuable, consider sharing it with your friends and followers on social media. Your share can help others discover this content too. Let’s spread knowledge together. Your support is greatly appreciated!”