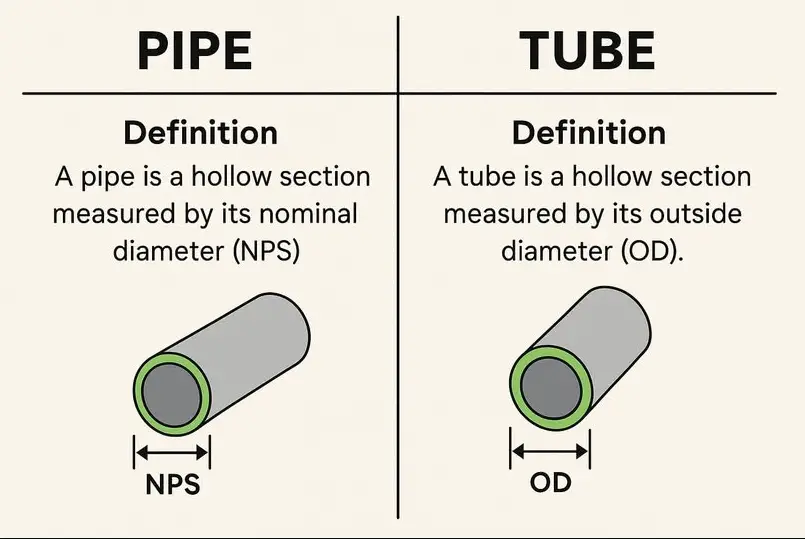

While pipes and tubes may look similar, they are designed for different purposes and have distinct characteristics. Here’s a breakdown of their differences:

1. Primary Purpose

| Feature | Pipe | Tube |

|---|---|---|

| Main Use | Transport fluids/gases (e.g., water, oil, gas) | Structural applications (e.g., frames, machinery, heat exchangers) |

| Pressure Handling | Designed for high-pressure systems | Typically used for low-pressure applications |

| Standardization | Follows Nominal Pipe Size (NPS) and schedules (e.g., SCH 40, SCH 80) | Measured by outside diameter (OD) & wall thickness (e.g., 1″ OD, 0.065″ wall) |

2. Size & Dimensions

| Feature | Pipe | Tube |

|---|---|---|

| Size Reference | Nominal Pipe Size (NPS) – Approximate ID (not exact) | Actual Outside Diameter (OD) – Precise measurement |

| Wall Thickness | Defined by schedule (e.g., SCH 40, SCH 80) | Measured directly (e.g., 0.125″, 2mm) |

| Tolerances | Looser tolerances (focus on pressure rating) | Tighter tolerances (precision applications) |

Example:

-

A 1″ Schedule 40 Pipe has:

-

Outside Diameter (OD) = 1.315″

-

Inside Diameter (ID) ≈ 1.049″

-

-

A 1″ Tube has:

-

OD = Exactly 1.0″

-

Wall thickness varies (e.g., 0.065″, 0.083″)

-

3. Shape & Flexibility

| Feature | Pipe | Tube |

|---|---|---|

| Shape | Mostly round (some square/rectangular for structural use) | Round, square, rectangular, oval |

| Flexibility | Rigid, designed for fixed installations | Can be more flexible (e.g., hydraulic tubes) |

4. Material & Manufacturing

| Feature | Pipe | Tube |

|---|---|---|

| Materials | Carbon steel, stainless steel, PVC, CPVC | Steel, aluminum, copper, brass, titanium |

| Production | Made for large-scale fluid transport | Made for precision applications (e.g., medical, aerospace) |

| Surface Finish | Rough (often coated for corrosion resistance) | Smooth (polished for aesthetics/functionality) |

5. Connection Methods

| Feature | Pipe | Tube |

|---|---|---|

| Joining | Welded, threaded, flanged | Welded, brazed, compression fittings, flared ends |

| Fittings | NPT (National Pipe Thread), socket weld | Ferrule fittings, push-to-connect |

6. Applications

Common Uses of Pipes:

-

Water supply lines

-

Oil & gas pipelines

-

Plumbing & HVAC systems

-

Industrial process piping

Common Uses of Tubes:

-

Structural frameworks (e.g., handrails, scaffolding)

-

Hydraulic & pneumatic systems

-

Heat exchangers & condensers

-

Automotive & aerospace components

Quick Summary Table

| Aspect | Pipe | Tube |

|---|---|---|

| Purpose | Fluid/gas transport | Structural/precision uses |

| Size Reference | Nominal Pipe Size (NPS) | Exact OD & wall thickness |

| Shape | Mostly round | Round, square, rectangular |

| Tolerances | Looser | Tighter |

| Pressure Handling | High | Low-medium |

| Joining Method | Threaded, welded, flanged | Compression, brazing, welding |

When to Use Pipe vs. Tube?

-

Use Pipes for: Plumbing, oil/gas, high-pressure systems.

-

Use Tubes for: Structural support, machinery, precision applications.