Hello friends welcome to SolidWorks tutorial. In this tutorial we will learn SolidWorks Drawings: Avoid These Common Errors . In our previous tutorial we learned Top 5 SolidWorks Add-ins you should use. If you want to learn SolidWorks from scratch you can buy my SolidWorks Complete Course on Udemy.

Related Posts-:

- Create Keyboard Shortcut in SolidWorks

- How to Speed Up SolidWorks Performance

- Copy Settings Wizard in SolidWorks

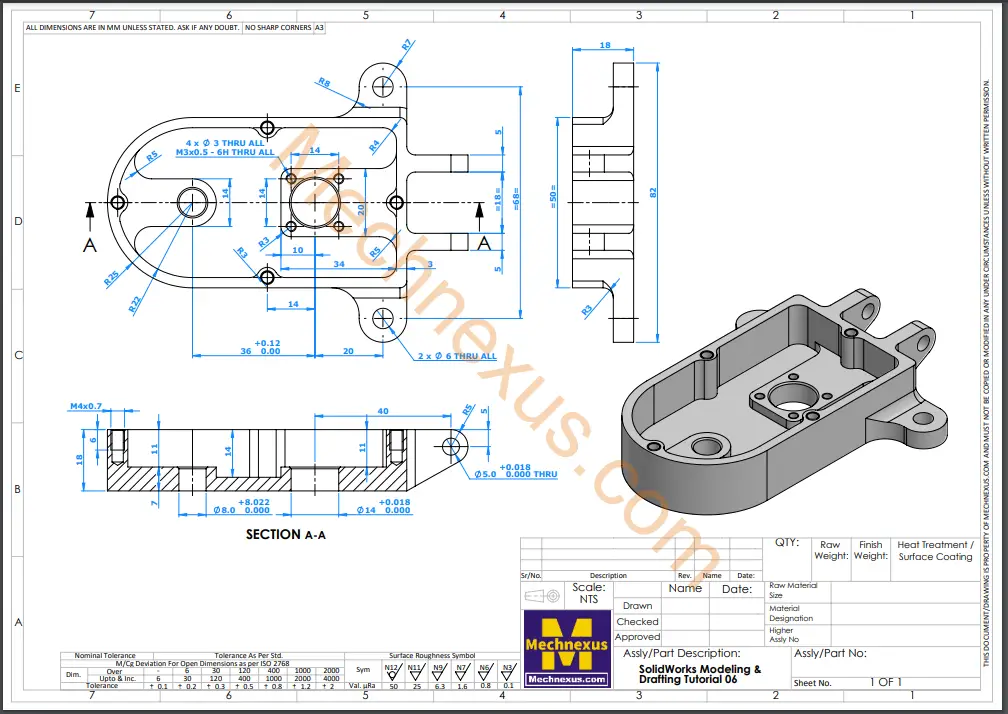

Creating accurate and professional drawings in SolidWorks is crucial for effective communication and manufacturing. However, even experienced users can make mistakes that lead to errors, misinterpretations, or production issues. Here are common errors in SolidWorks drawings and how to avoid them:

1. Incorrect or Missing Dimensions-:

- Error: Over-dimensioning, under-dimensioning, or missing critical dimensions.

- How to Avoid:

- Use Smart Dimension to ensure all necessary dimensions are included.

- Follow GD&T (Geometric Dimensioning and Tolerancing) standards where applicable.

- Double-check dimensions for accuracy and clarity.

2. Poor Layer and Line Formatting-:

- Error: Inconsistent or incorrect use of line types, weights, and layers.

- How to Avoid:

- Use predefined layers for different line types (e.g., visible edges, hidden lines, centerlines).

- Follow company or industry standards for line formatting.

- Ensure lines are clear and distinguishable.

3. Overcrowded Views-:

- Error: Placing too many views or details on a single sheet, making the drawing cluttered and hard to read.

- How to Avoid:

- Use multiple sheets if necessary.

- Focus on essential views (e.g., front, top, side) and add detail views or sections as needed.

- Maintain adequate spacing between views and annotations.

4. Incorrect Scale-:

- Error: Using an inappropriate scale for the drawing, making it too small or too large.

- How to Avoid:

- Choose a scale that fits the sheet size and ensures clarity.

- Use standard scales (e.g., 1:1, 1:2, 2:1) unless a custom scale is necessary.

- Verify the scale in the drawing properties.

5. Missing or Incorrect Tolerances-:

- Error: Failing to specify tolerances or using incorrect tolerance values.

- How to Avoid:

- Apply tolerances to critical dimensions based on manufacturing requirements.

- Use Tolerance/Precision settings in the dimension properties.

- Consult with manufacturing teams to ensure tolerances are realistic.

6. Inconsistent Annotation Placement-:

- Error: Placing annotations (e.g., notes, dimensions, symbols) haphazardly, leading to confusion.

- How to Avoid:

- Align annotations neatly and consistently.

- Use Collinear/Concentric alignment tools for dimensions.

- Group related annotations together for better readability.

7. Incorrect Use of Section and Detail Views-:

- Error: Misusing section or detail views, making the drawing unclear or misleading.

- How to Avoid:

- Use section views to reveal internal features and detail views to highlight small or complex areas.

- Clearly label section lines and detail boundaries.

- Ensure section and detail views are properly scaled and oriented.

8. Missing Title Block or Incorrect Information-:

- Error: Forgetting to include a title block or filling it with incorrect information.

- How to Avoid:

- Use a standardized title block template.

- Double-check all fields (e.g., part name, drawing number, revision, scale, date).

- Update the title block for each revision.

9. Ignoring Drawing Standards-:

- Error: Not adhering to industry or company-specific drawing standards.

- How to Avoid:

- Familiarize yourself with relevant standards (e.g., ASME, ISO, DIN).

- Use predefined templates that comply with these standards.

- Regularly review and update your knowledge of drawing standards.

10. Failing to Validate the Drawing-:

- Error: Not reviewing the drawing for errors before finalizing it.

- How to Avoid:

- Use Design Checker to validate the drawing against predefined standards.

- Perform a manual review to catch any overlooked errors.

- Share the drawing with colleagues or manufacturing teams for feedback.

Bonus Tips

- Use Drawing Templates: Save time and ensure consistency by using standardized templates.

- Leverage Layers: Organize drawing elements using layers for better control and clarity.

- Keep It Simple: Avoid unnecessary complexity; focus on clarity and functionality.

- Stay Updated: Regularly update your SolidWorks skills and knowledge to leverage new features and best practices.

By avoiding these common errors, you can create clear, accurate, and professional SolidWorks drawings that effectively communicate your design intent and ensure smooth manufacturing processes.

“Thank you for reading! If you found this article insightful and valuable, consider sharing it with your friends and followers on social media. Your share can help others discover this content too. Let’s spread knowledge together. Your support is greatly appreciated!”