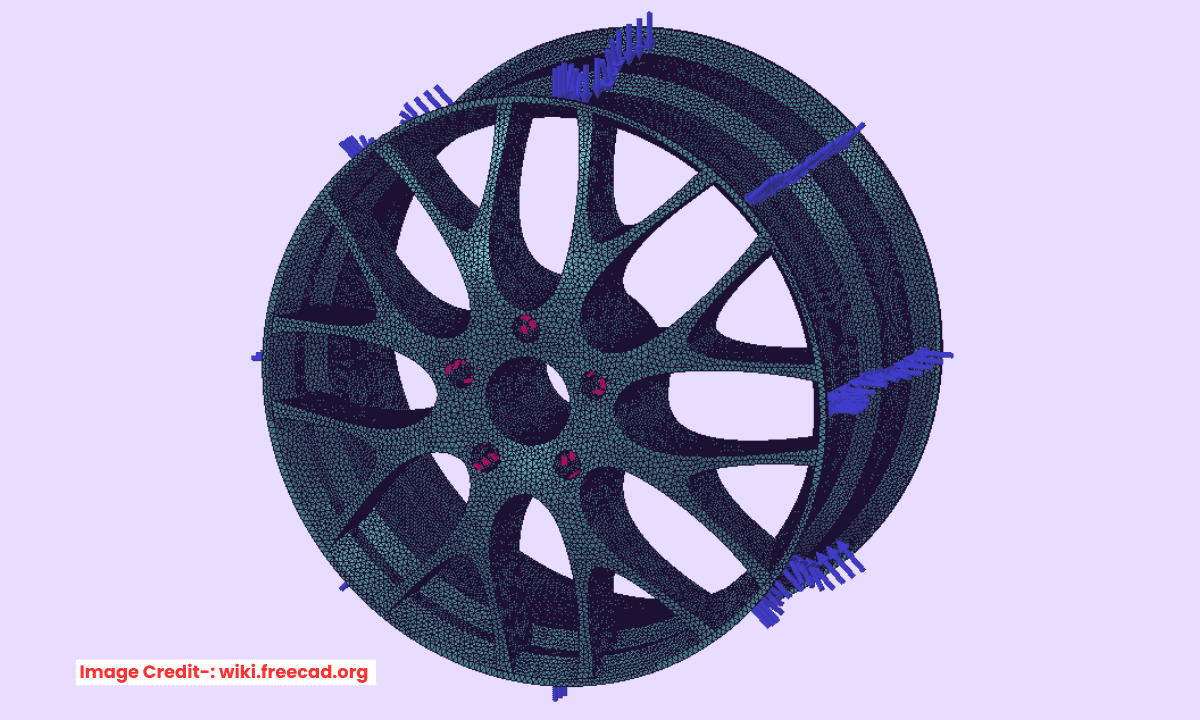

In Finite Element Analysis (FEA), the mesh discretizes a continuous geometry into small, simple elements. The accuracy of the solution is directly tied to the quality of this mesh. From a mechanical engineering standpoint, good meshing is a balance between computational cost and result fidelity.

Key principles include:

-

Element Type Selection: Use higher-order elements (e.g., quadratic tetrahedrons) when modeling complex geometries or capturing stress gradients, as they better represent curved boundaries and complex deformation patterns. Lower-order elements are simpler but less accurate.

-

Mesh Refinement: Concentrate a finer mesh in critical regions of high-stress gradients, such as around holes, fillets, and sharp corners. A coarse mesh in these areas will significantly underestimate the true maximum stress, leading to non-conservative designs.

-

Mesh Quality Metrics: The software provides metrics to check mesh quality. Strive for elements that are as regular as possible.

-

Aspect Ratio: Avoid long, skinny elements; aim for a ratio close to 1.

-

Skewness: Highly skewed (distorted) elements can produce inaccurate results.

-

Jacobian: This measures the deviation of an element from its ideal shape; a positive value is essential.

-

-

Convergence Study: This is the most critical practice for an engineer. Systematically refine the global mesh or key areas and observe the solution (e.g., max stress, deflection). When the result changes negligibly between refinements, the solution has converged, indicating a mesh that is sufficiently accurate.

The goal is not a perfect mesh, but a mesh that is “fit for purpose”—one that provides a result accurate enough for the design decision at hand without unnecessary computational expense. A well-executed mesh is the foundation for trusting your FEA results.

In FEA, the mesh is the foundation of your simulation. A poor mesh leads to unreliable results, no matter how advanced your setup. Follow these core principles to ensure accuracy.

1. The Goldilocks Zone: Mesh Density-:

The goal is a mesh that is appropriately fine—not too coarse, not unnecessarily dense.

-

Coarse Mesh: Fast to solve but inaccurate. It misses stress concentrations and can severely underestimate maximum stresses.

-

Fine Mesh: More accurate but computationally expensive. The key is to refine only where needed.

2. Target Stress Concentrations-:

Automatically refining the mesh in high-stress areas is the most critical step for accuracy.

-

Use Stress Concentrations: Apply mesh refinements near holes, fillets, sharp corners, and any area where you expect high stress.

-

Capture Gradients: The mesh must be fine enough to capture the steep gradient (change) in stress. A coarse mesh will “average out” the peak stress, giving a deceptively low and dangerous result.

3. Prioritize Element Quality-:

A fine mesh with poor-quality elements is worse than a coarser, high-quality one.

-

Aspect Ratio: Avoid long, skinny elements. Aim for elements that are as close to equilateral (e.g., squares/cubes) as possible. High aspect ratios can cause numerical stiffness and inaccuracies.

-

Skewness & Jacobian: These metrics check how “distorted” an element is. Most pre-processors have tools to check mesh quality. Always review these reports before solving.

4. Choose Your Element Type Wisely-:

-

Tetrahedrons (Tets): Great for complex geometries. However, lower-order “linear” tets can be too stiff. Use “quadratic” (second-order) tets for better accuracy, especially for stress analysis.

-

Hexahedrons (Hexes): Generally more accurate and efficient with fewer elements. Use them for simpler, block-like geometries or swept volumes.

5. Perform a Convergence Study-:

This is the definitive check for mesh adequacy.

-

Run an analysis with a initial mesh.

-

Refine the mesh globally or in critical areas.

-

Run the analysis again.

-

Compare the results (e.g., max stress, max displacement).

-

Keep refining until the results change by an acceptably small percentage (e.g., <2-5%).

When the results stop changing significantly with a finer mesh, your solution has converged.

The Bottom Line: A good mesh is not just fine; it’s intelligently refined. Focus your computational power where the physics demands it—at the critical points of your design.

“Thank you for reading! If you found this article insightful and valuable, consider sharing it with your friends and followers on social media. Your share can help others discover this content too. Let’s spread knowledge together. Your support is greatly appreciated!”