This is an excellent and critical mindset for any engineer working with simulation. The phrase “Don’t Trust Your FEA” underscores the need for a rigorous process to ensure your results are credible. This process is known as Verification and Validation (V&V).

Here is a guide to understanding and implementing V&V for your finite element analyses.

🔎 What is V&V? The Crucial Difference-:

It’s vital to understand that Verification and Validation are two distinct but complementary processes. A simple way to remember the difference is:

-

Verification: Are we solving the equations correctly? (Solving the problem right)

-

Validation: Are we solving the correct equations? (Solving the right problem)

This table breaks down the core distinctions:

| Aspect | Verification | Validation |

|---|---|---|

| Core Question | “Is the model solved correctly?” | “Does the model represent reality?” |

| Primary Focus | Mathematical correctness and numerical accuracy of the solution. | Physical accuracy and relevance of the model itself. |

| Common Methods | – Mesh Convergence Studies – Mathematical Checks (e.g., rigid body modes, unit load tests) – Element Shape Quality Checks |

– Comparison with Experimental Data (e.g., strain gauges) – Comparison with Analytical Solutions for Simplifications – Benchmarking against Established Cases |

| Who Typically Does It? | Primarily the FEA analyst. | Analyst in collaboration with test engineers. |

📝 The V&V Process: A Step-by-Step Guide-:

Building a credible model is an iterative process. Here are the key steps to follow, synthesizing best practices from industry resources.

Step 1: Verification – Building the Model Correctly-:

Before you can trust your results, you must ensure your model is built and solved without numerical errors.

-

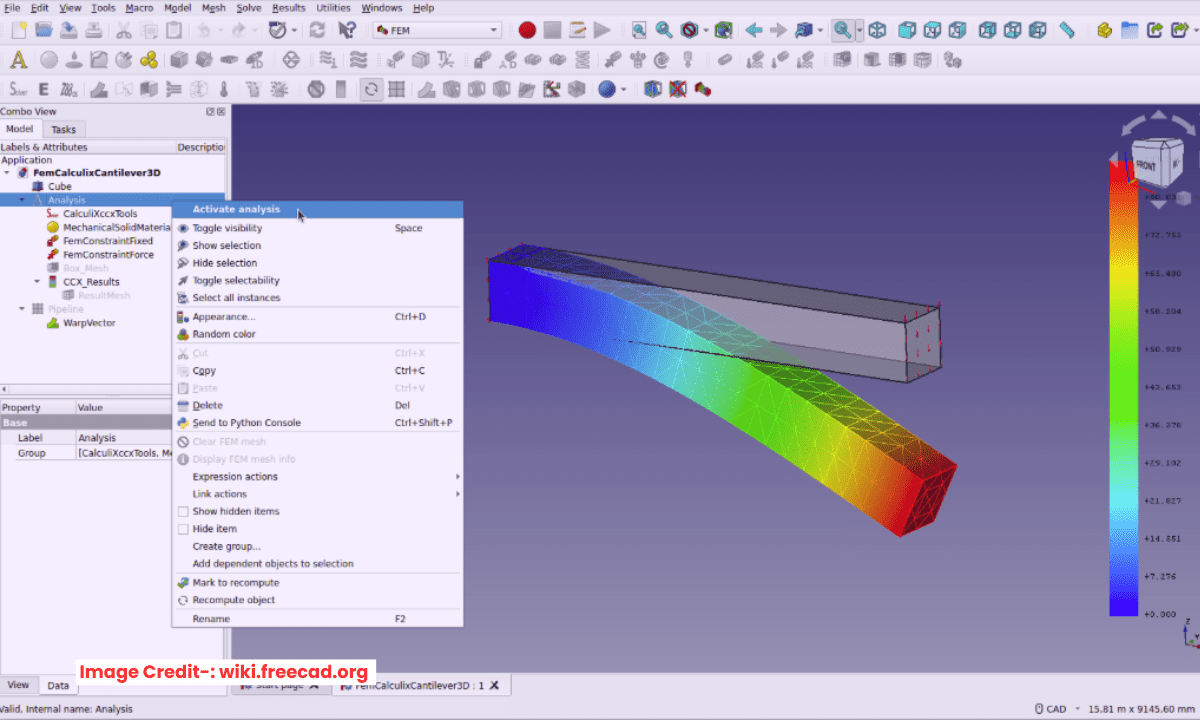

Conduct Mesh Convergence Studies: This is arguably the most critical verification step. Refine your mesh in critical areas and observe key results (like max stress or displacement). A “converged” solution is one where these results stop changing significantly with a finer mesh.

-

Perform Mathematical Sanity Checks: Run simple checks to ensure your model behaves as expected mathematically:

-

Unit Gravity Check: Apply a 1G load and verify that the reaction forces equal the model’s weight.

-

Rigid Body Mode Check: For an unconstrained model, a free-free modal analysis should produce zero-frequency rigid body modes.

-

-

Inspect Geometry and Mesh Quality: Use automated tools to check for and fix common issues like gaps, overlapping surfaces, and duplicate nodes that can cause solver errors. Also, check for highly distorted elements with poor aspect ratios.

-

Validate Inputs and Balance Loads: Double-check that material properties, loads, and boundary conditions are applied correctly. Always ensure that the sum of reacted loads balances the sum of applied loads in each direction.

Step 2: Validation – Ensuring the Model Matches Reality-:

A mathematically sound model can still be physically wrong. Validation bridges this gap.

-

Compare with Experimental Data: The gold standard for validation is comparing FEA results with physical test data. Strain gauges are a common and reliable method for this. The physical component is instrumented with gauges, subjected to known loads, and the measured strains are directly compared to the FEA predictions.

-

Use Analytical Solutions: For simpler problems or specific sub-components, compare your FEA results with closed-form analytical solutions. A difference of less than 10% is often considered a good correlation for complex models.

-

Document the Correlation: Maintain a “FEM Validation Report” that documents the correlation process. This should include locations of gauges, test conditions, comparisons between FEA and test data, and explanations for any discrepancies.

💡 Why Bother? The Consequences of Skipping V&V-:

Ignoring V&V is a significant business and engineering risk.

-

False Confidence: A beautifully colored plot that is wrong can lead you to believe a flawed design is safe, or a good design is faulty. This can “lead the design process in the wrong direction”.

-

Costly Mistakes: Decisions based on incorrect simulation data can result in failed prototypes, wasted manufacturing costs, and even catastrophic product failures in the field.

-

Lack of Credibility: For product certification or in regulated industries, a documented V&V process is often mandatory to prove your simulations are reliable.

The most successful engineering teams treat V&V not as an optional last step, but as an integral part of their simulation workflow from the very beginning.

I hope this guide helps you build more reliable and trustworthy simulations. If you’d like to dive deeper into any specific method, such as designing a convergence study or planning a strain gauge test, please feel free to ask.

“Thank you for reading! If you found this article insightful and valuable, consider sharing it with your friends and followers on social media. Your share can help others discover this content too. Let’s spread knowledge together. Your support is greatly appreciated!”