Springs are mechanical components designed to store and release energy, absorb shock, or maintain a force between surfaces. From a mechanical engineering standpoint, their design and selection are governed by fundamental principles to ensure they meet specific functional requirements without failure.

The primary consideration is the Spring Rate (k), defined by Hooke’s Law (F = kx). It defines the stiffness—the force required to deflect the spring a unit distance. A high spring rate is stiff; a low rate is flexible.

Key design parameters include:

-

Load and Deflection: The maximum operating force and the required travel distance are the starting points.

-

Space Constraints: The available envelope limits the spring’s dimensions (e.g., mean diameter, free length).

-

Material Selection: This is critical for performance and longevity. Common choices include:

-

Music Wire: General purpose, high strength.

-

Stainless Steel: For corrosive environments.

-

Phosphor Bronze: For non-magnetic conductivity.

-

-

Stress and Endurance: Engineers must calculate the maximum shear stress to prevent yielding. For dynamic applications (cyclic loading), fatigue life analysis is essential to predict the number of cycles until failure.

The main types are:

-

Compression Springs: Resist pushing forces. Design must consider solid height (when coils touch) and end type (e.g., closed, ground).

-

Extension Springs: Resist pulling forces. They typically have hooks or loops and are designed with an initial tension.

-

Torsion Springs: Resist twisting forces, applying a torque.

Ultimately, spring design is a compromise between load, deflection, stress, and space. Engineers use these parameters, guided by standards like ASME or manufacturer catalogs, to select or custom-design a spring that is both functional and durable for its application.

Springs are fundamental components that store and release energy, absorb shock, or maintain force between surfaces. Selecting the right spring is a systematic process of balancing load, deflection, space, and environment.

Step 1: Understand the Spring Types and Their Primary Functions-:

First, identify which type of spring fits your application’s mechanical function.

-

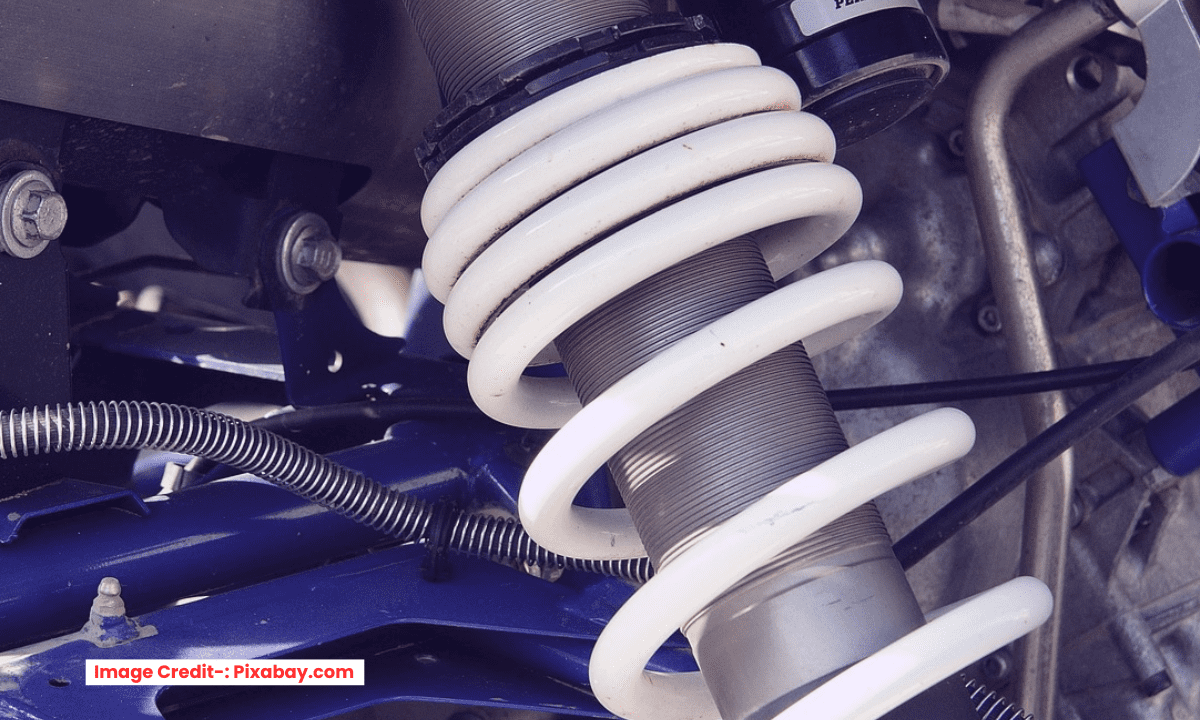

Compression Springs: The most common type. Designed to resist a compressive force. Applications: Automotive suspensions, pens, valves.

-

Extension Springs: Designed to resist a stretching force. Typically have hooks or loops at the ends. Applications: Garage doors, weighing scales, trampolines.

-

Torsion Springs: Designed to resist a twisting force (torque) applied about the spring axis. Applications: Clothespins, mousetraps, door hinges.

-

Constant Force Springs: Provide a nearly constant force over a long deflection. Applications: Retractable seatbelts, tape measures.

-

Belleville Washers (Disc Springs): Handle very high loads in a small space and are useful for compensating for thermal expansion or maintaining bolt preload. Applications: Bolted joints, heavy-duty valves, clutch assemblies.

Step 2: Define Your Core Design Requirements-:

Before looking at a catalog, you need clear specifications. Ask these questions:

-

Load (Force or Torque): What is the force the spring needs to exert or resist at its operating length? (e.g., 50 N of force at the compressed height).

-

Deflection (Travel): What is the distance the spring needs to travel from its free length to its operating length?

-

Space Constraints: What are the limits for the spring’s outer diameter (OD), inner diameter (ID), and solid height (fully compressed)?

-

Operating Environment: Temperature? Exposure to corrosive chemicals? This dictates material choice.

-

Spring Rate (Stiffness): How much force is required to deflect the spring a unit distance? (k = Force / Deflection). A high spring rate is stiff; a low rate is soft.

Step 3: Apply the Spring Design Fundamentals-:

The physics of a common helical compression or extension spring is governed by two key equations:

-

Spring Rate (Stiffness):

k = (G * d^4) / (8 * D^3 * N_a)-

k= Spring Rate (N/mm or lb/in) -

G= Shear Modulus of the material (e.g., ~79 GPa for steel) -

d= Wire Diameter -

D= Mean Coil Diameter -

N_a= Number of Active Coils

What this tells you: Stiffness is highly sensitive to wire diameter (

d^4). A small change indcreates a large change ink. A larger coil diameter (D) or more active coils makes the spring softer. -

-

Shear Stress (The Critical Check for Failure):

τ = (8 * F * D * K_w) / (π * d^3)-

τ= Shear Stress in the wire (MPa or psi) -

F= Applied Force -

K_w= Wahl Correction Factor (accounts for stress concentration due to wire curvature)

What this tells you: You must ensure the calculated shear stress (

τ) is below the allowable shear stress for your chosen material. This prevents the spring from taking a permanent set or failing. -

Step 4: Select the Right Material-:

Material choice is a balance of strength, cost, and environmental resistance.

-

Music Wire (ASTM A228): The gold standard. High strength, excellent fatigue life, and relatively low cost. General-purpose use.

-

Stainless Steel (302/316): For corrosive environments or non-magnetic applications. 316 has better corrosion resistance.

-

Chrome Silicon / Chrome Vanadium: Alloy steels with higher fatigue strength and temperature resistance than music wire. Used in demanding applications like automotive valve springs.

-

Inconel / Elgiloy: High-temperature exotic alloys for extreme environments (e.g., aerospace, down-hole tools).

-

Phosphor Bronze / Beryllium Copper: Good for corrosive environments and electrical conductivity.

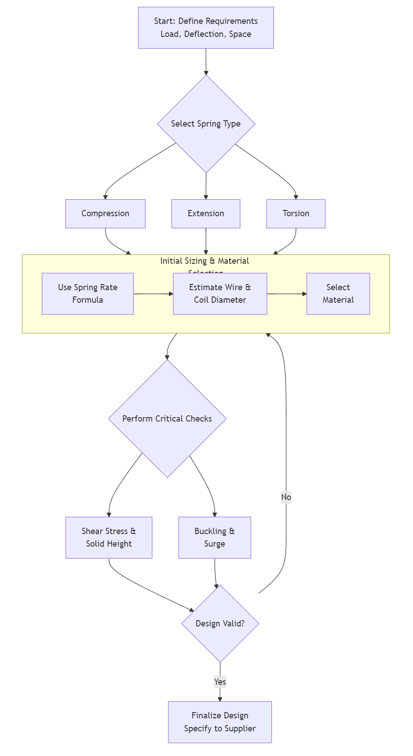

The Spring Selection & Design Process

The following flowchart visualizes the iterative process of selecting and validating a spring design:

Pro Tips for a Robust Design

-

Avoid Solid Height: Never design a spring to operate at its solid height. Leave a safety margin.

-

Check for Buckling: Slender compression springs (high free length to diameter ratio) can buckle under load. Use guides or refer to buckling charts.

-

Consider Fatigue Life: For dynamically loaded springs (e.g., in an engine), you must perform a fatigue analysis using the alternating stress (

τ_alt). -

Specify to Your Supplier: When ordering, provide at minimum: Spring Type, Material, Free Length, Wire Diameter, Outer/Inner Diameter, Number of Coils, and Load at a specific Travel.

By following this structured approach—defining needs, understanding the physics, and iterating through the design checks—you can confidently select or design a spring that will perform reliably in your application.

“Thank you for reading! If you found this article insightful and valuable, consider sharing it with your friends and followers on social media. Your share can help others discover this content too. Let’s spread knowledge together. Your support is greatly appreciated!”