Kinematics is the study of motion without considering the forces that cause it. In mechanism design, it is the foundational step for ensuring a device moves as intended. A mechanical engineer uses kinematics to analyze and define the position, velocity, and acceleration of all parts within a mechanical system.

The primary role of kinematics is to translate a desired overall function into a specific, predictable motion. This process involves:

-

Synthesis: Creating a conceptual arrangement of links and joints (a linkage) to produce a required motion. For example, designing a four-bar linkage so the output rocker traces a specific path.

-

Analysis: Mathematically modeling the proposed mechanism to calculate the precise path, speed, and acceleration of its components. This is crucial for identifying potential issues like interference, undesired dwells, or unrealistic velocities before any physical prototyping.

-

Degrees of Freedom (DOF): Using Gruebler’s/Kutzbach’s criterion to determine the number of independent inputs required to control the mechanism predictably. A structure with zero DOF cannot move, while one with multiple DOFs is unstable without sufficient actuators.

By rigorously applying kinematics, engineers can optimize performance, ensure safety, and verify that the mechanism’s motion meets the design requirements. It separates the geometry of motion from the stresses and forces (dynamics), allowing the engineer to perfect the movement itself before sizing components to withstand the loads. In essence, kinematics provides the “choreography” for the machine’s parts, ensuring they are in the right place at the right time.

Here is a clear explanation of the fundamental role kinematics plays in mechanism design.

The Role of Kinematics in Mechanism Design-:

Kinematics is the study of motion without considering the forces that cause it. In mechanism design, it is the foundational science used to ensure your device moves as intended, before you ever worry about whether the components are strong enough.

Think of it this way:

-

Kinematics answers: “Will it move the right way?”

-

Dynamics (the next step) answers: “Is it powerful/strong enough to move that way?”

Kinematics is the first and most critical check in creating a functional mechanism.

The Core Question Kinematics Answers-:

Kinematics provides the mathematical framework to predict and analyze:

-

Position: Where is every part of the mechanism at any given point in time?

-

Velocity: How fast are the parts moving?

-

Acceleration: How quickly are the parts speeding up or slowing down?

Why Kinematics is Indispensable in Design-:

1. It Enables Motion Planning and Synthesis-:

This is the proactive use of kinematics. Before modeling a single part, you can use kinematic principles to synthesize a mechanism that produces a desired output motion from a given input.

-

Example: You need a windshield wiper arm that sweeps through a specific angle. Using kinematics, you can determine the optimal lengths of the wiper’s four-bar linkage and the required rotation of the motor to achieve that exact sweep, without any physical prototyping.

2. It Ensures the Mechanism is Constrained Correctly-:

A fundamental concept in kinematics is Degrees of Freedom (DOF)—the number of independent movements a mechanism has.

-

The Goal: A well-designed mechanism typically has 1 DOF. A single input (e.g., a motor rotating) produces a single, predictable output.

-

The Problem: If the DOF is zero, the mechanism is locked. If it’s greater than one, it’s under-constrained and can move in unpredictable ways.

-

Kinematic Analysis uses formulas (like Gruebler’s Equation) to quickly check this, preventing flawed designs early on.

3. It Defines the Mechanism’s “Workspace”-:

The workspace (or “reachable envelope”) is the total volume in space that a mechanism can access.

-

Example (Robotics): For a robotic arm, kinematics is used to map out its entire reach. This ensures it can pick up a part from point A and place it at point B without colliding with itself or its environment.

-

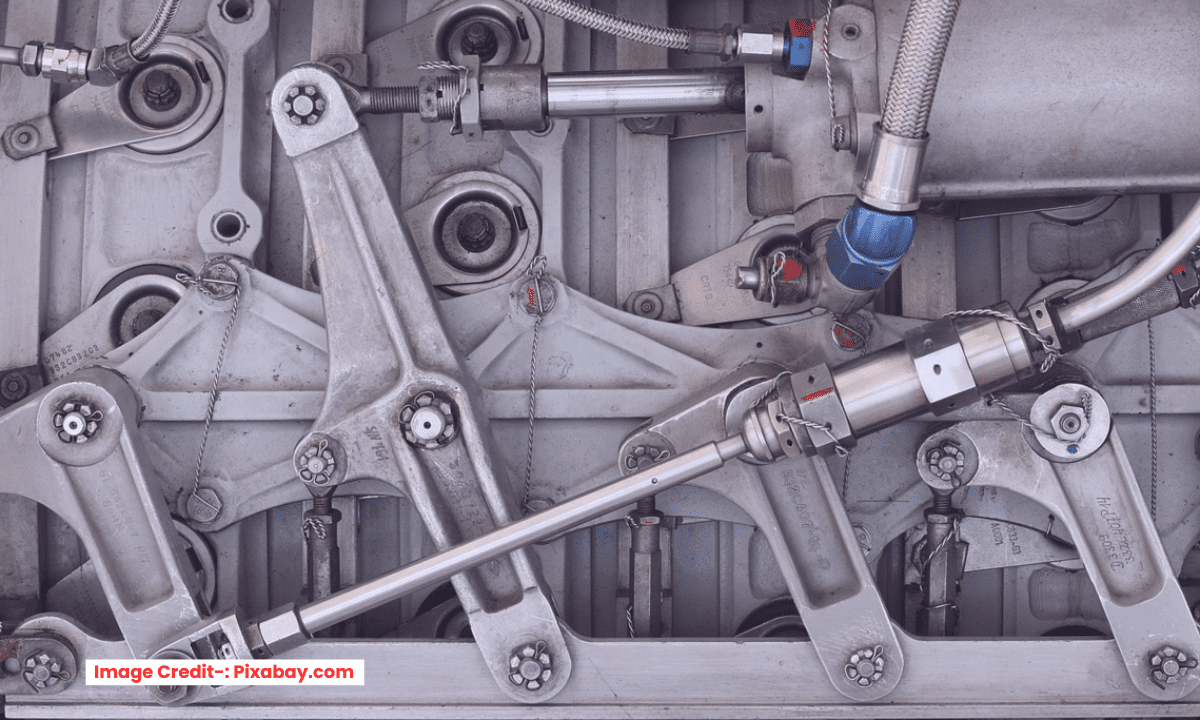

Example (Automotive): For a car’s suspension, the kinematic analysis determines the wheel’s path as it travels over a bump, ensuring optimal tire contact with the road.

4. It Predicts Performance and Uncovers Flaws-:

By calculating velocity and acceleration, kinematics helps you identify and avoid problems before they happen.

-

Avoiding High Acceleration: Sudden, high acceleration in a mechanism leads to high inertial forces, vibration, and wear. Kinematics helps you smooth out the motion profile.

-

Identifying “Singularities”: These are positions where the mechanism locks up or loses a degree of freedom (e.g., a fully extended robotic arm). Kinematic analysis pinpoints these failure points.

-

Preventing Interference: By knowing the precise path of every component, you can ensure they don’t collide during operation.

The Practical Workflow: From Kinematics to Completed Design-:

-

Kinematic Synthesis: Define the desired motion and use kinematic principles to conceptualize the type and proportions of the mechanism (e.g., a slider-crank, a four-bar linkage).

-

Kinematic Analysis: Model the chosen mechanism in software (like MATLAB, Adams, or SolidWorks Motion) to simulate its position, velocity, and acceleration. Verify it meets all motion requirements.

-

Dynamic Analysis: Once the motion is confirmed, add materials, masses, and forces to calculate the loads on each component. This is where you size your motors, bearings, and shafts.

-

Detailed Design & FEA: With the loads known from dynamics, you can now design the detailed geometry of each link and perform Finite Element Analysis (FEA) to ensure they are strong enough.

In a Nutshell

Kinematics is the blueprint for motion. It is the difference between creating a static structure and a dynamic, functional machine. By mastering kinematics, you move from guessing how something might work to knowing how it will work, saving immense time and cost in prototyping and preventing catastrophic design failures.

“Thank you for reading! If you found this article insightful and valuable, consider sharing it with your friends and followers on social media. Your share can help others discover this content too. Let’s spread knowledge together. Your support is greatly appreciated!”