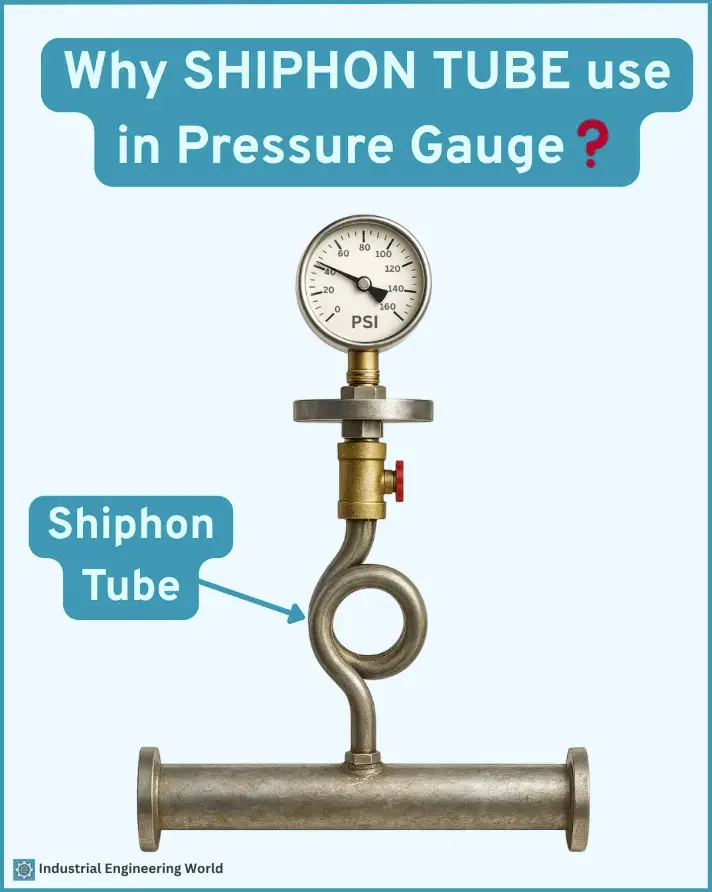

A siphon tube (also called a pressure gauge siphon or pigtail siphon) is a coiled or looped tube installed between a pressure gauge and the process line. It serves critical functions in protecting the gauge from damage caused by high temperatures, pressure surges, and corrosive media.

Key Reasons for Using a Siphon Tube

1. Protects Against High Temperature

-

Problem: Steam, hot gases, or high-temperature liquids can damage the pressure gauge’s internal mechanism (Bourdon tube).

-

Solution: The siphon tube cools the medium before it reaches the gauge by:

-

Creating a condensate trap (in steam applications).

-

Allowing heat dissipation through the coiled/looped design.

-

2. Prevents Pressure Surges & Pulsation Damage

-

Problem: Rapid pressure spikes (water hammer) or pulsating flows can fatigue the gauge.

-

Solution: The siphon tube dampens surges by:

-

Acting as a buffer zone that absorbs sudden pressure changes.

-

Reducing pulsation effects in systems like reciprocating pumps.

-

3. Blocks Corrosive/Dirty Media

-

Problem: Slurry, corrosive fluids, or particulate-laden gases can clog or corrode the gauge.

-

Solution: The siphon:

-

Traps condensate (in steam systems), preventing direct contact with hot/corrosive steam.

-

Allows sediments to settle instead of entering the gauge.

-

4. Maintains Gauge Accuracy & Longevity

-

By stabilizing temperature and pressure, the siphon extends the gauge’s life and ensures consistent readings.

Common Applications of Siphon Tubes

✔ Steam Lines (Boilers, HVAC, power plants)

✔ Hot Liquids (Oil, chemical processes)

✔ Pulsating Systems (Reciprocating pumps, compressors)

✔ Corrosive/Dirty Media (Slurry, gas pipelines)

Types of Siphon Tubes

-

Coil Siphon (Pigtail) – Spiral design for compact installations.

-

U-Type Siphon – Simple loop for moderate temperatures.

-

Syphon with Cooling Fins – Enhanced heat dissipation.

How It Works

-

The siphon tube fills with condensate (in steam systems) or process fluid.

-

This liquid column blocks direct contact between the gauge and extreme heat/pressure.

-

Pressure is transmitted hydraulically through the trapped liquid, protecting the gauge.

When is a Siphon Tube NOT Needed?

-

Low-temperature systems (<80°C / 176°F).

-

Non-pulsating, clean fluids (e.g., compressed air, water at ambient temp).

Key Takeaway

A siphon tube is a small but crucial safety device that prevents gauge failure in harsh conditions. It ensures accurate pressure readings while protecting equipment from thermal, mechanical, and chemical damage.