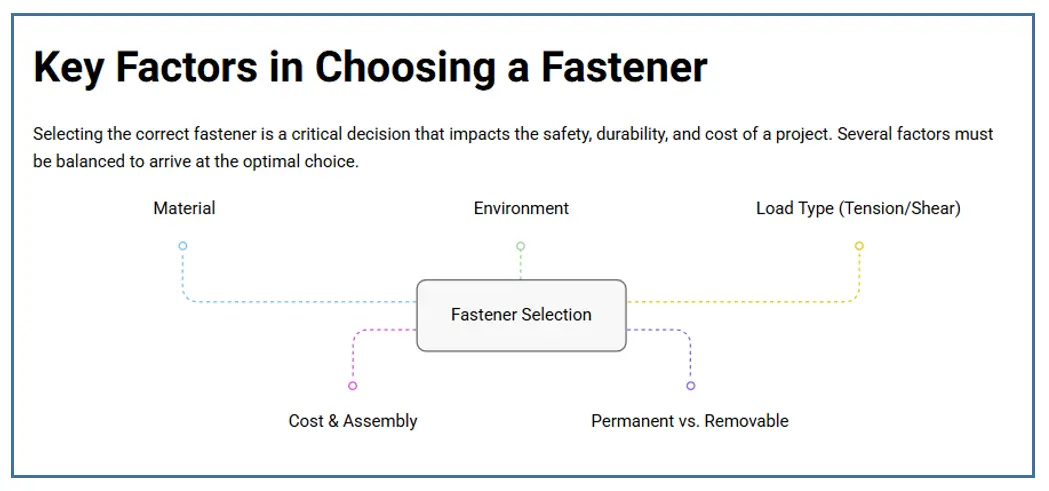

Selecting a fastener is a balance of function, cost, and manufacturability. The primary questions are: What are the load requirements? Is the joint permanent or need disassembly? What are the material and assembly constraints? Selecting the correct fastener—screws, bolts, or rivets—is a critical design decision that impacts a product’s structural integrity, assembly cost, and service life. The choice hinges on the joint’s functional requirements.

Bolts and Screws are threaded fasteners used for demountable joints. The key distinction is that bolts use a nut for clamping, while screws typically thread into a tapped hole in one of the components.

-

When to use: For assemblies requiring disassembly for maintenance, repair, or adjustment.

-

Key Considerations:

-

Strength: Grade (SAE) or Class (ISO) defines the bolt’s tensile and yield strength.

-

Load Type: Bolts are excellent in shear and tension. For high shear loads, shoulder bolts or fitted bolts are used.

-

Thread Engagement: Sufficient depth must be designed to ensure failure occurs in the bolt, not the stripped threads.

-

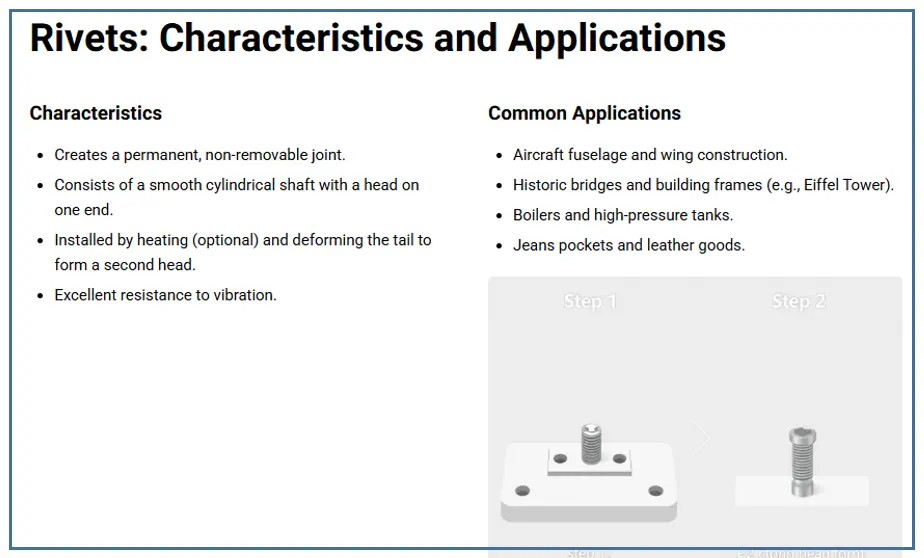

Rivets are permanent mechanical fasteners. A protruding head is formed on one end by deforming the rivet’s tail.

-

When to use: For low-cost, high-volume, permanent assemblies where disassembly is not intended (e.g., aircraft fuselages, bridges, sheet metal enclosures).

-

Key Considerations:

-

Permanence: They create a robust, vibration-resistant joint but must be drilled out for disassembly, damaging the components.

-

Shear Strength: Excellent for shear load applications.

-

Installation: Often faster to install than bolts but require access to both sides of the joint (except for specialty blind rivets).

-

The fundamental trade-off is serviceability vs. permanence and cost. Engineers must analyze the load path, environmental conditions (e.g., corrosion requiring specific materials), required preload, and total life-cycle costs to make the optimal selection.

Choosing the right fastener is critical for the integrity, cost, and serviceability of your design. Here’s a practical guide to selecting between screws, bolts, and rivets.

Related posts:

- Beginner Guide to Computer Aided Design

- Best Mechanical Design Software 2025

- How AI in CAD Market Transforming Growth

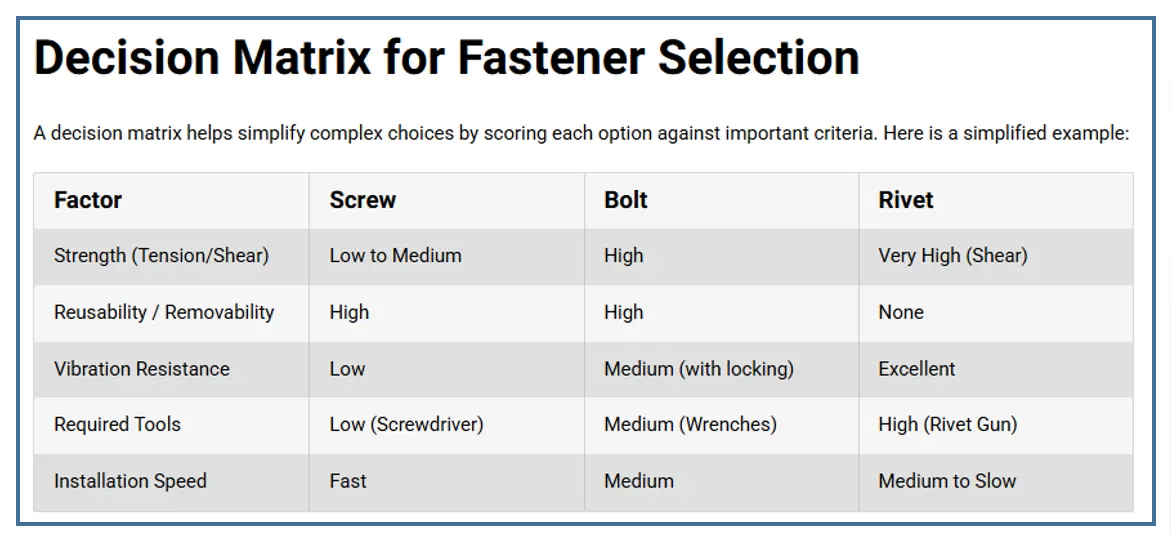

The Quick-Reference Comparison Table-:

| Fastener Type | Primary Use | Key Characteristics | Installation | Best For… |

|---|---|---|---|---|

| Screws | Joining components to a threaded surface (pre-tapped hole or integrated thread-forming). | Generally smaller, tightened by turning the head. Many head styles (pan, flat, hex) and drive types (Phillips, Torx, hex). | Threads into the mating part. Often installed with a screwdriver or driver bit. | Light-to-moderate loads, sheet metal, electronics, appliances, assemblies requiring disassembly. |

| Bolts | Clamping parts together using a nut. | Pass through unthreaded clearance holes and are secured with a nut on the other side. | Requires wrenches on both ends (head and nut). | Heavy-duty structural connections, high pre-load, machinery, automotive frames, and steel construction. |

| Rivets | Permanent fastening of two or more parts. | A head on one side, and a deformed “shop head” on the other. Cannot be removed without destruction. | Installed by deforming the tail. Requires access to only one side (“blind” rivets). | Permanent joints where welding isn’t ideal, lightweight structures (aircraft, bridges), sheet metal, and blind applications. |

Deep Dive: When to Use Each Fastener-:

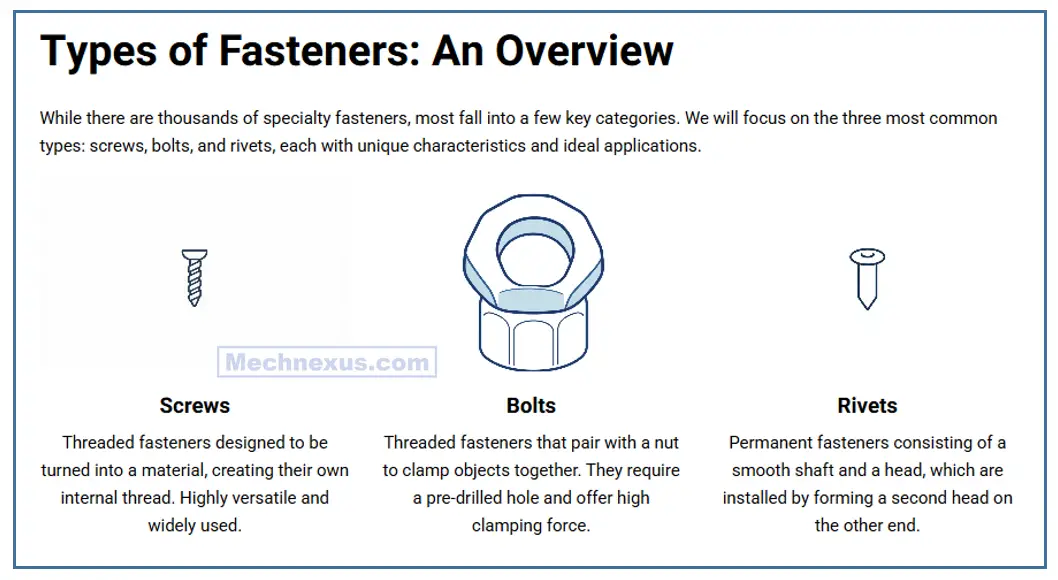

1. Screws: The All-Purpose Threaded Fastener-:

A screw is an externally helical threaded fastener capable of being tightened or released by a twisting force (torque) to the head. The most common uses of screws are to hold objects together and there are many forms for a variety of materials. Screws might be inserted into holes in assembled parts or a screw may form its own thread. The difference between a screw and a bolt is that the latter is designed to be tightened or released by torquing a nut. Screws are your go-to for creating a strong, threaded connection directly into a material.

-

Thread-Forming Screws: (e.g., Sheet Metal Screws) They cut or form their own mating thread as they are driven. Excellent for soft materials like plastic, wood, and sheet metal.

-

Machine Screws: Designed to be used with a pre-tapped hole or a nut. Common in machinery, electronics, and appliances.

-

Self-Drilling Screws: Have a drill point, eliminating the need for a pre-drilled pilot hole. Huge time-saver in sheet metal work.

Choose Screws When:

-

You are fastening into a threaded or thread-forming material.

-

The joint requires disassembly for service or repair.

-

Loads are light to moderate.

-

You have access to only one side of the joint during assembly.

2. Bolts: The High-Strength Clamping Solution-:

A bolt is an externally helical threaded fastener capable of being tightened or released by a twisting force (torque) to a matching nut. The bolt has an external male thread requiring a matching nut with a pre-formed female thread. Bolts are characterized by their use with a nut, which allows for very high clamping force (pre-load). This pre-load is what creates a strong, rigid joint.

-

The Clamping Force is Key: A properly torqued bolt stretches slightly, clamping the parts together. The friction between the clamped parts then carries the load, not the shear strength of the bolt itself.

-

Grades Matter: Bolts are graded (e.g., Grade 5, Grade 8, SAE) or classed (e.g., Class 8.8, 10.9, 12.9), indicating their tensile strength. Always specify the grade.

Choose Bolts When:

-

The joint is structural and carries high loads.

-

You need a high, predictable clamping force.

-

The connected parts are too thin or soft to be threaded reliably.

-

You have access to both sides of the joint.

3. Rivets: The Permanent, One-Side Solution-:

A rivet is a permanent mechanical fastener. Before being installed, a rivet consists of a smooth cylindrical shaft with a head on one end. The end opposite the head is called the tail. On installation, the deformed end is called the shop head or buck-tail.

Because there is effectively a head on each end of an installed rivet, it can support tension loads. However, it is much more capable of supporting shear loads (loads perpendicular to the axis of the shaft).

Rivets create a permanent mechanical lock by physically deforming the fastener itself.

-

Solid Rivets: The strongest type. Require access to both sides and are “bucked” with a hammer or pneumatic tool. Common in aircraft and structural steel (bridges).

-

Blind Rivets (Pop Rivets): The most common type for general manufacturing. Installed from one side using a specialized rivet gun. The mandrel is pulled, deforming the rivet body.

Choose Rivets When:

-

The joint needs to be permanent and vibration-resistant.

-

You only have access to one side of the assembly (“blind” application).

-

The materials being joined are dissimilar or cannot be welded easily.

-

The primary load is shear (across the rivet shaft).

Related posts:

- FreeCAD Integration with KiCAD

- Beginner Guide to Computer Aided Design

- AI copilot for Computer-Aided Design (CAD) Software

The Selection Checklist: 5 Key Questions-:

Ask these questions to guide your choice:

-

Is Disassembly Required?

-

Yes: Use Screws or Bolts/Nuts.

-

No: Rivets are a top contender.

-

-

What is the Primary Load Type?

-

Shear Load: Rivets and Bolts (in clearance holes) excel here.

-

Tension / Clamping: Bolts are superior due to high pre-load. Screws can work for lower loads.

-

-

Do You Have Access to Both Sides?

-

One Side Only: Blind Rivets or Self-Tapping Screws.

-

Both Sides: Bolts & Nuts, Solid Rivets, or Screws into a tapped hole.

-

-

What are the Materials?

-

Soft Materials (plastic, thin sheet metal): Thread-forming screws or rivets.

-

Hard/Brittle Materials (cast iron): Bolts & nuts or tapped holes with high-strength screws.

-

-

What are the Cost and Assembly Speed Requirements?

-

Lowest Cost/High Speed: Blind Rivets or Self-Drilling Screws can be installed very quickly with minimal tooling.

-

High Strength/Precision: Bolts, which require more time for torquing and often need washers.

-

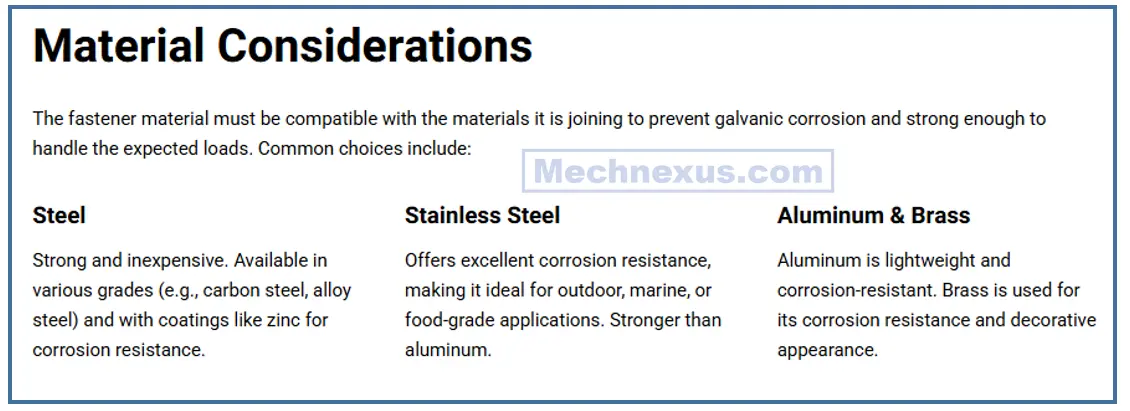

Material Consideration in Fasteners Selection-:

Material selection for fasteners is a critical engineering decision that directly impacts the integrity, longevity, and safety of an assembly. The primary considerations are the mechanical properties, environmental conditions, and cost.

Mechanical Properties: The fastener material must possess adequate strength (tensile and yield) to withstand applied loads without fracturing or deforming. This is often defined by the fastener’s property class (e.g., Grade 5 or 8 for steel). Hardness is also crucial to prevent thread galling and wear, but it must be balanced with a degree of ductility to absorb shock and vibration without becoming brittle.

Environmental Conditions: This is often the most decisive factor. For corrosion resistance, choices range from carbon steel (with plating or coatings like zinc or cadmium) for mild environments to stainless steel (e.g., 304 or 316) for more aggressive ones. For extreme corrosion or high-purity applications, alloys like Monel or Hastelloy, or even non-metallics like titanium, may be necessary. Temperature is another key driver; high-temperature applications may require alloys like A286 or Inconel, while cryogenic services often need specific austenitic stainless steels.

Other Considerations: Weight can be a factor in aerospace or automotive applications, favoring materials like aluminum or titanium, though often at a higher cost. Galvanic corrosion must be prevented by selecting a fastener material that is electrochemically similar to the components being joined. Finally, cost is always a practical constraint, balancing initial material expense with the required performance and service life.

In summary, fastener material selection is a compromise between achieving the necessary mechanical performance, ensuring durability in the service environment, and managing overall project costs.

By systematically evaluating your joint requirements against these criteria, you can confidently select the fastener that ensures a safe, reliable, and cost-effective design.

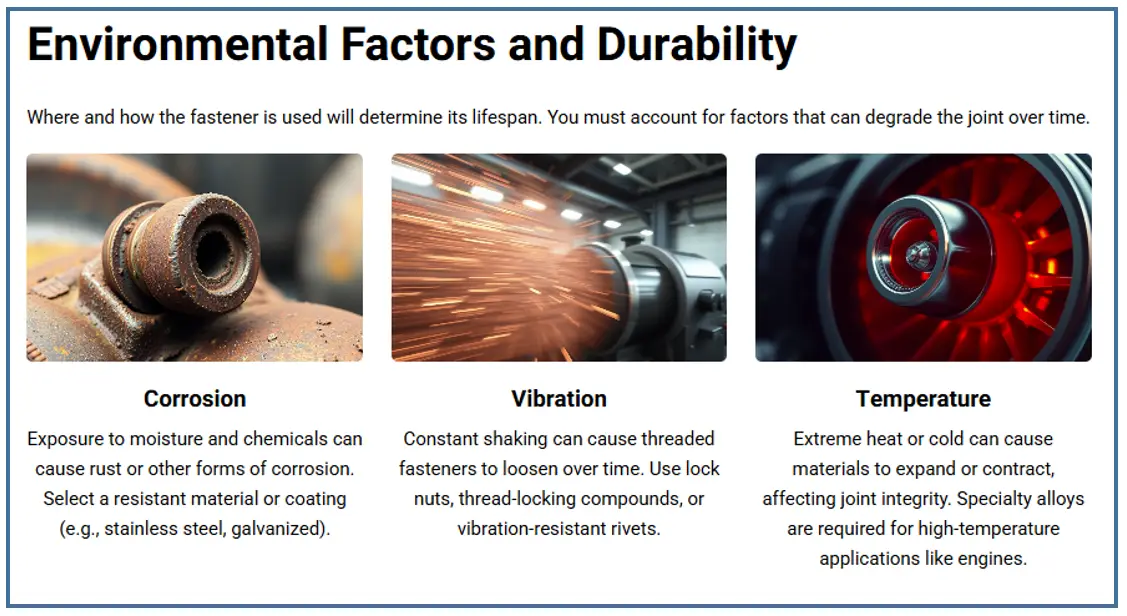

Factor that Determine Lifespan of Fasteners-:

The lifespan of a fastener is determined by a complex interplay of factors that can cause it to fail prematurely. Understanding these is key to ensuring joint integrity and safety.

1. Environmental Corrosion: This is the most common lifespan limiter. Exposure to moisture, salts, acids, or industrial chemicals leads to rust and pitting, which progressively reduces the fastener’s cross-sectional area and strength. Galvanic corrosion, caused by contact between dissimilar metals, can aggressively destroy a fastener. The material and coating selection (e.g., zinc-plated steel vs. stainless steel vs. titanium) is the primary defense.

2. Mechanical Loads: Fasteners are designed for specific loads. Static overload (exceeding yield or tensile strength) causes immediate failure. More insidious is fatigue failure, caused by repeated cyclic loads below the static strength limit. This leads to crack initiation and propagation, ultimately resulting in a sudden, brittle fracture. Proper preload (clamp force) is critical to minimize fatigue loads on the fastener itself.

3. Operational Stresses: Vibration is a major culprit, as it can cause a joint to loosen over time, losing the essential clamp force and leading to fatigue or shear failure. Abrasion from particulate matter or relative motion can wear down protective coatings and the fastener itself, accelerating corrosion and reducing strength.

4. Temperature Extremes: High temperatures can cause creep (slow, permanent deformation under load) and anneal the material, softening it and reducing its strength. Conversely, extremely low temperatures can embrittle some materials. Thermal cycling can also induce fatigue stresses.

5. Installation and Maintenance: Improper installation, such as incorrect torque leading to under-tightening or over-tightening, drastically shortens lifespan. A lack of periodic inspection and re-tightening in critical applications can allow minor issues to develop into catastrophic failures.

In essence, a fastener’s lifespan is a battle against its operational environment and loads. Maximizing it requires the correct initial selection of material and coating, proper installation, and a design that minimizes dynamic stresses and corrosion potential.

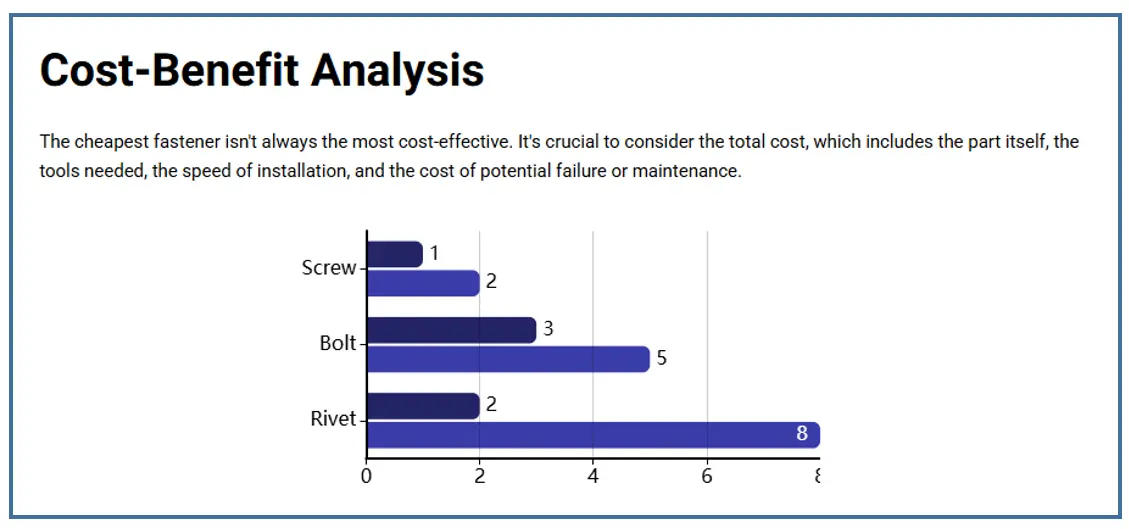

Fasteners Cost-Benefits Analysis-:

A cost-benefit analysis for fasteners moves beyond initial purchase price to evaluate the total cost of ownership, balancing upfront expenditure against long-term performance and risk.

The lowest-cost fastener (e.g., basic carbon steel) often carries the highest long-term risk. Its susceptibility to corrosion, lower strength, and potential for premature failure can lead to catastrophic expenses from unplanned downtime, product damage, repair labor, and safety liabilities. The “benefit” of a low initial price is quickly negated by these failure costs.

Conversely, a higher-grade fastener (e.g., stainless steel, high-strength alloy, or specialty coated) presents a greater upfront investment but delivers significant benefits that reduce total cost. These include:

-

Enhanced Reliability: Reduced risk of unexpected failure and downtime.

-

Longer Lifespan: Better corrosion and fatigue resistance extends service intervals and reduces replacement frequency.

-

Lower Maintenance: Corrosion-resistant materials avoid the labor and cost of regular inspections, re-tightening, and replacements.

The most cost-effective choice is the one that provides the necessary performance and reliability at the lowest total cost. For a non-critical, easily accessible application in a benign environment, a standard fastener is economically rational. However, for critical, safety-related, or hard-to-reach applications in harsh environments, the higher initial investment in a superior fastener is justified, as its benefits directly mitigate much larger potential costs. The analysis must weigh the consequences of failure against the premium for prevention.

Decision Matrix for Fasteners Selection-:

Related posts:

- JETCAM Introduces a Free Tool for Viewing CAD Files

- Beginner Guide to Computer Aided Design

- Best Mechanical Design Software 2025

“Thank you for reading! If you found this article insightful and valuable, consider sharing it with your friends and followers on social media. Your share can help others discover this content too. Let’s spread knowledge together. Your support is greatly appreciated!”