CNC Machining and 3D Printing represent two fundamentally different manufacturing philosophies: subtractive versus additive. CNC is a subtractive process, where a solid block of material (metal, plastic, or composite) is carved away by a rotating cutting tool to form the final part. In contrast, 3D Printing, or Additive Manufacturing, builds parts layer-by-layer from the ground up, using materials like plastic resin, filament, or metal powder.

This core difference drives their respective strengths and weaknesses. CNC Machining excels in producing parts with exceptional strength, tight tolerances, and superior surface finishes. It works with a vast range of engineering-grade materials, making it ideal for functional, high-stress components. However, its subtractive nature can lead to significant material waste, and its complexity is limited by the tool’s ability to access geometries, often requiring multiple setups.

3D Printing thrives on geometric freedom, allowing for the creation of intricate internal lattices, undercuts, and organic shapes that are impossible for CNC. It is highly efficient with material, generates little waste, and has minimal setup costs, making it perfect for rapid prototyping and complex, low-volume parts. Its primary drawbacks include generally lower strength (due to its layered structure), a smaller selection of materials, and often a need for post-processing to achieve a smooth finish.

Related Posts:

- Top 10 Courses to Join After Mechanical Engineering

- BRL-CAD: Open-Source Software for Military Engineering

- 3DViewStation Bridges Gap Between Engineers and Suppliers

The choice between them hinges on the project’s requirements. Choose CNC for high-strength, precision parts in end-use applications, especially with metals. Choose 3D Printing for rapid prototyping, highly complex geometries, and custom, low-volume parts where design iteration speed is critical. Together, they form a complementary toolkit for modern digital manufacturing.

The choice hinges on understanding the core processes: CNC is subtractive (material is removed from a solid block), while 3D Printing is additive (material is built up layer by layer). This fundamental difference dictates their optimal applications.

The choice between CNC machining and 3D printing depends heavily on your project’s specific needs, as each excels in different areas. To put it simply: choose 3D printing for complex prototypes, intricate designs, and low-volume runs; choose CNC machining for high-strength, high-precision parts with excellent surface finishes, especially at higher volumes.

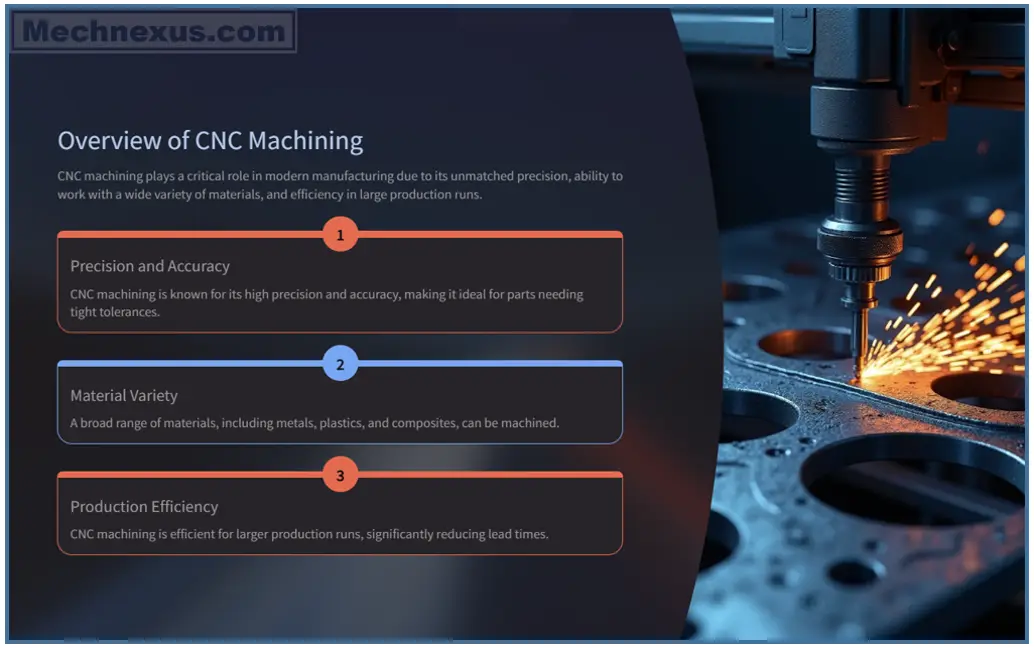

Overview of CNC Machining-:

CNC (Computer Numerical Control) machining is a foundational modern manufacturing process that uses pre-programmed computer software to dictate the movement of factory tools and machinery. It is a subtractive method, where material is systematically removed from a solid block (or workpiece) to create a custom-designed part. This contrasts with additive manufacturing (3D printing), which builds parts layer by layer.

The process begins with a digital CAD (Computer-Aided Design) model of the part. This model is then translated into manufacturing instructions by CAM (Computer-Aided Manufacturing) software, which generates the G-code. This code controls all aspects of the machine’s operation, including the speed and position of the cutting tools, coolant flow, and spindle rotation.

Key CNC machines include:

-

Mills: Utilize rotating multi-point cutting tools to remove material from a stationary workpiece.

-

Lathes: Rotate the workpiece against a stationary cutting tool to produce cylindrical parts.

-

Routers and Grinders: Used for larger parts or achieving fine surface finishes, respectively.

The primary advantages of CNC machining are its high precision, repeatability, and complexity. It can produce parts with extremely tight tolerances from a vast range of materials, including metals, plastics, and composites. Once a program is verified, a CNC machine can run unattended for hours, producing identical components with minimal variation.

Related posts:

- Ultimate Guide to Landing Your First Mechanical Engineering Job

- How to Negotiate Your Engineering Salary Like a Pro

- Future-Proof Mechanical Engineer: Skills for the Next Decade

As a result, CNC machining is indispensable across industries for prototyping and end-use part production. It is crucial for creating everything from complex aerospace components and medical implants to custom automotive engines and consumer electronics. While initial setup and programming can be intensive, its ability to reliably create high-quality, complex geometries makes it a cornerstone of digital manufacturing.

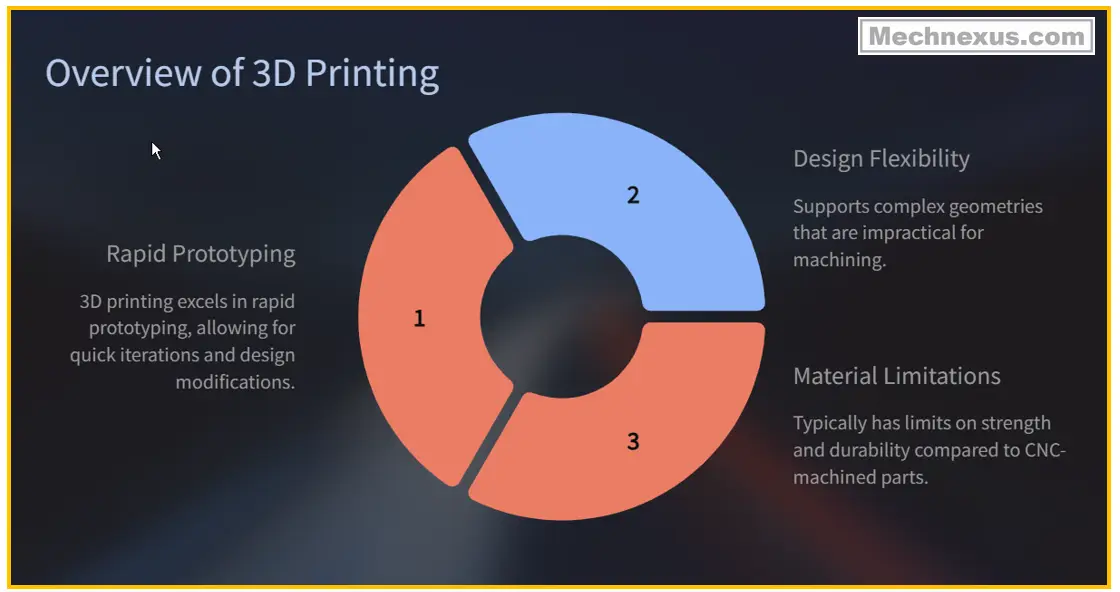

Overview of 3D Printing-:

3D printing, or Additive Manufacturing (AM), is a process of creating three-dimensional solid objects from a digital file. Unlike traditional subtractive methods that remove material from a block, 3D printing builds parts layer by layer, adding material only where needed. This fundamental principle allows for the creation of highly complex geometries that are often impossible or prohibitively expensive to produce with other techniques.

The process begins with a 3D model, typically designed in CAD (Computer-Aided Design) software. This digital model is then “sliced” by specialized software into ultra-thin horizontal cross-sections. The sliced file guides the printer as it deposits or solidifies material, building the object one layer at a time. Common technologies include Fused Deposition Modeling (FDM), which extrudes a thermoplastic filament; Stereolithography (SLA), which uses a laser to cure liquid resin; and Selective Laser Sintering (SLS), which fuses powdered material with a laser.

The primary advantages of 3D printing are its unparalleled design freedom, rapid prototyping capabilities, and customization. It eliminates the need for expensive tooling, making it cost-effective for one-off parts and low-volume production. It is widely used for creating functional prototypes, custom medical implants, architectural models, lightweight aerospace components, and intricate consumer goods.

However, limitations include generally slower production speeds for large volumes, often inferior mechanical strength compared to machined parts due to its layered nature, and a need for post-processing to achieve a smooth surface finish. Despite these constraints, 3D printing remains a transformative technology, enabling rapid innovation and on-demand manufacturing across countless industries.

Related Posts:

- Ultimate Guide to Landing Your First Mechanical Engineering Job

- How to Negotiate Your Engineering Salary Like a Pro

- Future-Proof Mechanical Engineer: Skills for the Next Decade

Here is a direct comparison of their core characteristics to help you understand the key differences.

| Feature | CNC Machining | 3D Printing (Additive Manufacturing) |

|---|---|---|

| Process | Subtractive: Cuts away material from a solid block. | Additive: Builds parts layer-by-layer from the ground up. |

| Best For | High strength, precision, and smooth finishes. | Complex geometries, rapid prototyping, and low-volume custom parts. |

| Material Options | Very wide range: metals (aluminum, steel), plastics, wood, and composites. | More limited but growing; primarily plastics and some metals. |

| Material Strength | Parts have the full, isotropic strength of the original material. | Strength can be anisotropic (weaker along the layer lines) and is often lower than the native material. |

| Precision & Finish | High precision and tight tolerances (as low as ±0.025 mm); superior surface finish. | Good accuracy, but generally lower precision (typically around ±0.1-0.5 mm); visible layer lines are common. |

| Cost Effectiveness | Higher setup cost, but more economical for medium to high-volume production. | Lower setup cost, ideal for 1-10 parts; cost per part doesn’t drop significantly with volume. |

| Design Flexibility | Limited by tool access; internal geometries and undercuts can be challenging or impossible. | Very high freedom; can create intricate internal structures, hollow parts, and organic shapes easily. |

| Material Waste | Generates significant waste (chips and shavings) from the raw block. | Low waste; uses only the material needed for the part and supports. |

🛠️ How to Make the Right Choice for Your Project-:

To decide which technology is best for you, consider the following questions about your project:

-

What is the primary purpose of the part?

-

For visual or form-and-fit prototypes, 3D printing is typically faster and cheaper.

-

For functional prototypes and end-use parts that must withstand stress, heat, or force, CNC machining produces parts with superior mechanical properties.

-

-

How complex is your part’s geometry?

-

If your design has complex internal channels, lattice structures, or organic shapes, 3D printing is the clear winner.

-

For parts with simpler, more traditional geometries, CNC machining can produce them with high precision and a smooth finish.

-

-

How many parts do you need?

-

For low volumes (1-10 parts), 3D printing is usually more cost-effective due to near-zero setup costs.

-

For medium to high volumes (10-100+ parts), CNC machining often becomes more economical, as the high setup cost is spread across many units.

-

-

What material properties are critical?

-

If you need a part made from a specific, high-strength metal alloy or engineering plastic, CNC machining offers a much wider selection.

-

If you need flexible materials or are working with specialized metal superalloys that are difficult to machine, 3D printing may be the better option.

-

-

What is your budget and timeline?

Ultimately, there is no single “best” technology—only the best one for your specific project. By carefully weighing your requirements for purpose, complexity, volume, and material, you can confidently select the manufacturing process that will deliver the right result.

Related Posts:

- Ultimate Guide to Landing Your First Mechanical Engineering Job

- From Mechanical Design Engineer to Engineering Manager: Making the Leap

- How to Negotiate Your Engineering Salary Like a Pro

I hope this comparison helps you make an informed decision. If you’re willing to share more details about your specific part, such as its intended use, material needs, or approximate quantity, I may be able to offer more tailored insights.

“Thank you for reading! If you found this article insightful and valuable, consider sharing it with your friends and followers on social media. Your share can help others discover this content too. Let’s spread knowledge together. Your support is greatly appreciated!”