In machinery, bearings are not just components; they are foundational enablers of motion and efficiency. Their core function is to support a rotating shaft (or axle) while minimizing friction and handling loads. This seemingly simple task is what makes them indispensable in virtually every machine, from a simple electric fan to a jet engine.

The Primary Importance of Bearings Rests on Three Pillars:

-

Friction Reduction and Efficiency: By using rolling elements (balls or rollers) between moving and stationary parts, bearings replace high-friction sliding contact with low-friction rolling contact. This dramatically reduces power loss due to heat and wear, directly translating to higher mechanical efficiency and lower energy consumption.

-

Load Support and Structural Integrity: Bearings are the critical interface that transfers loads from the rotating shaft to the stationary machine housing. They are precisely engineered to handle different load types—radial (perpendicular to the shaft) and axial (parallel to the shaft). This ensures the shaft remains positioned correctly, preventing catastrophic misalignment, excessive deflection, and structural failure under operational forces.

-

Precision and Motion Control: High-precision bearings allow for smooth, controlled rotation with minimal vibration and runout. This is not just about smooth operation; it is critical for accuracy. In machine tools, robotics, and medical equipment, this precision directly defines the quality and capability of the machine.

Without bearings, shafts would wobble excessively, friction would rapidly overheat and seize components, and power transmission would be grossly inefficient. They are the unsung heroes that enable the speed, precision, and reliability that define modern mechanical systems. Their failure is often catastrophic, leading to immediate and costly machine downtime, underscoring their critical role in mechanical design and maintenance.

Selecting the right bearing is a critical design decision that balances load, speed, precision, and cost to ensure longevity and reliable performance. The process begins by analyzing the application’s fundamental requirements.

The Primary Considerations are:

-

Load Type and Magnitude:

-

Radial Load: Perpendicular to the shaft. Ball bearings are typically suitable for moderate radial loads.

-

Axial/Thrust Load: Parallel to the shaft. Tapered roller or thrust ball bearings are designed for high axial loads.

-

Combined Load: A mix of both. Deep-groove ball bearings can handle light combined loads, but angular contact ball bearings or tapered roller bearings are superior for significant combined loading.

-

-

Operating Speed: Ball bearings, with their point contact, generate less heat and friction at high speeds than roller bearings (line contact). For very high speeds, precision ball bearings or specialized fluid-film bearings are chosen.

-

Accuracy and Rigidity: Machine tool spindles require high-precision, pre-loaded bearings to minimize deflection and runout. Roller bearings generally offer greater rigidity than ball bearings.

-

Environmental Conditions: Harsh environments dictate material and sealing. Stainless steel bearings resist corrosion, while shielded or sealed bearings retain lubricant and exclude contaminants like dust or moisture.

Common Bearing Types & Their Niche:

-

Ball Bearings: General purpose, moderate load and speed, low cost.

-

Roller Bearings (Cylindrical, Spherical, Tapered): High radial load capacity, tolerate misalignment (spherical), handle combined loads (tapered).

-

Plain Bearings (Bushings): High load and low speed, compact, excellent for oscillatory motion.

The final choice is an optimization, often balancing the higher cost of a robust bearing against the operational cost of premature failure and downtime.

Choosing the right bearing is a systematic process critical to the performance and longevity of your machine. Here’s a structured guide to help you select the optimal bearing for your application.

Related Posts:

- How to Build a Killer Mechanical Engineering Resume

- Top 10 Interview Questions for Mechanical Engineers

- Pros and Cons of Being a Mechanical Engineer Consultant

The 5 Key Selection Criteria-:

Ask yourself these five questions to narrow down your options effectively.

1. What are the LOAD Type and Magnitude?

This is the most critical factor.

-

Radial Load: Perpendicular to the shaft.

-

Axial (Thrust) Load: Parallel to the shaft.

-

Combined Load: A mix of both radial and axial loads.

Bearing Type Guide:

-

Primarily Radial Load: Deep Groove Ball Bearings are excellent.

-

High Radial & Moderate Axial Load: Angular Contact Ball Bearings or Tapered Roller Bearings.

-

Pure Axial Load: Thrust Ball Bearings (for low speed) or Cylindrical Roller Thrust Bearings (for high load).

-

Very High Radial Load: Cylindrical Roller Bearings or Spherical Roller Bearings.

2. What is the Required SPEED (RPM)?

Friction, heat generation, and centrifugal force are key concerns at high speeds.

-

High RPM: Ball Bearings are generally superior due to their low friction and point contact.

-

Low to Moderate RPM: Roller Bearings can be used, excelling where load capacity is more critical than speed.

3. What is the Needed MISALIGNMENT Capability?

Can the housing and shaft be held in perfect alignment?

-

Perfect Alignment: Most standard bearings (Deep Groove, Cylindrical Roller) are suitable.

-

Shaft/Housing Deflection or Misalignment: Self-Aligning Bearings like Spherical Roller Bearings or Self-Aligning Ball Bearings are essential to prevent premature failure.

4. What are the PRECISION and RUNOUT Requirements?

Does the application demand high positional accuracy and smooth rotation (e.g., machine tool spindles)?

-

Commercial/General Use: Standard ABEC 1 (ISO Normal) tolerance is sufficient.

-

High Precision/Speed: Specify higher precision grades like ABEC 3, 5, or 7 (ISO Class 6, 5, or 4), common in Precision Angular Contact Bearings.

5. What is the OPERATING ENVIRONMENT?

Consider contaminants, temperature, and lubrication.

-

Harsh/Dirty Environments: Choose Sealed or Shielded Bearings. For highly corrosive or washdown environments, Stainless Steel (e.g., 440C, 316) or even Polymer (e.g., PEEK, Delrin) bearings are available.

-

High Temperatures: Require special heat-stabilized steels and high-temperature lubricants.

-

Lubrication Limitations: If re-lubrication is impossible, sealed “lubricated-for-life” bearings or specially coated Dry-Running Bearings are the solution.

Related Posts:

- Ultimate Guide to Landing Your First Mechanical Engineering Job

- How to Negotiate Your Engineering Salary Like a Pro

- Future-Proof Mechanical Engineer: Skills for the Next Decade

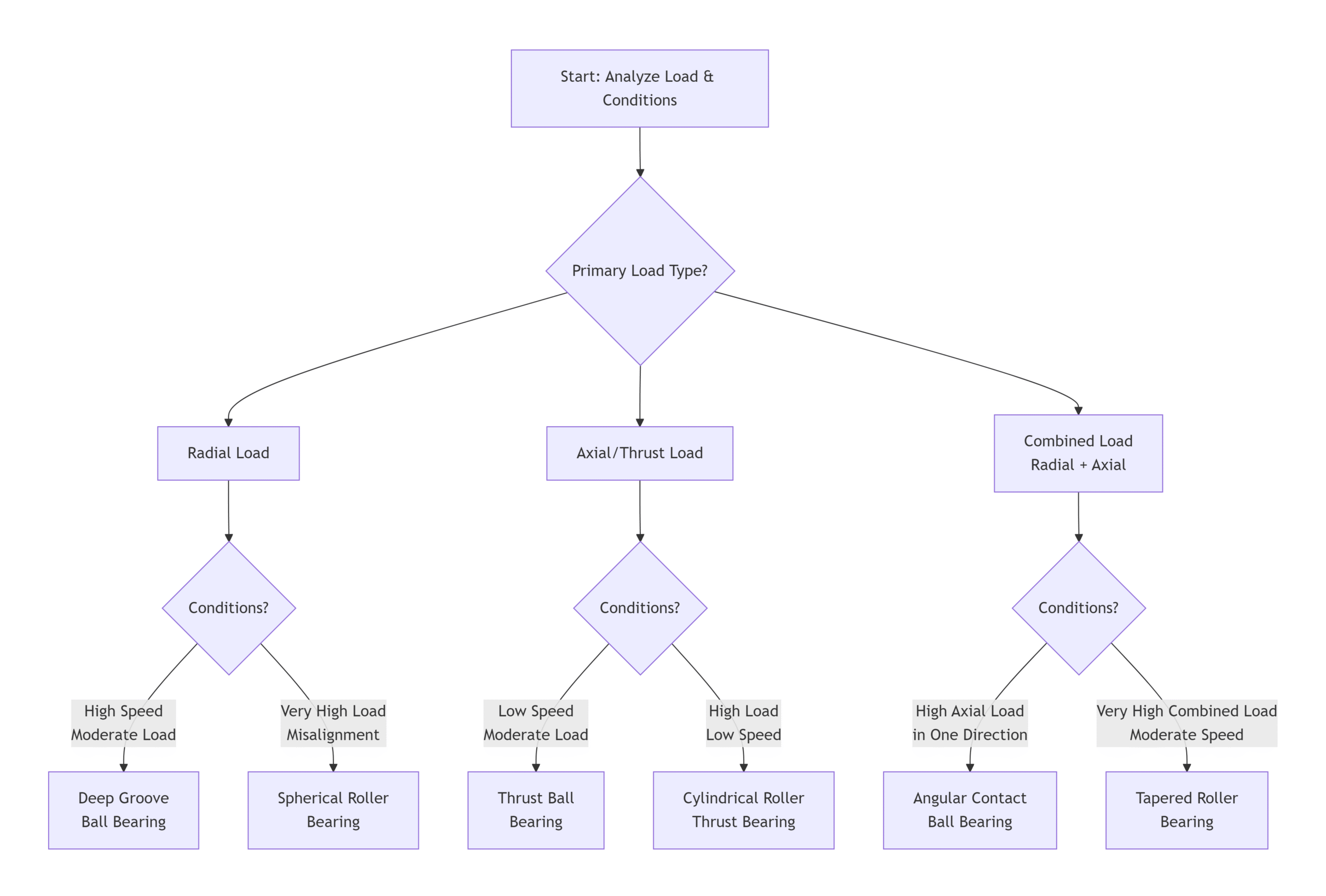

Bearing Type Selection Roadmap-:

Here is a visual decision tree to guide your initial selection based on the primary load and application needs:

Final Checklist & Pro Tips-:

-

Confirm Size Constraints: Ensure the bore, OD, and width fit your design envelope.

-

Consider Bearing Life (L10 Rating): Calculate the expected life based on your load and speed conditions. Manufacturers provide tools for this.

-

Pre-Load for Rigidity: In high-precision applications (like spindles), a pre-load is applied to eliminate internal clearance and increase system stiffness.

-

Don’t Forget Mounting: How will the bearing be fixed? Snap rings, adapter sleeves, or press fits? This influences the bearing type and design.

-

Consult a Supplier: When in doubt, contact a bearing manufacturer or distributor (like SKF, NSK, Timken). Their application engineers are an invaluable resource.

By systematically working through these criteria—Load, Speed, Misalignment, Precision, and Environment—you can confidently select a bearing that ensures reliability, efficiency, and a long service life for your mechanical system.

Related Posts:

- How to Build a Killer Mechanical Engineering Resume

- Top 10 Interview Questions for Mechanical Engineers

- Pros and Cons of Being a Mechanical Engineer Consultant

“Thank you for reading! If you found this article insightful and valuable, consider sharing it with your friends and followers on social media. Your share can help others discover this content too. Let’s spread knowledge together. Your support is greatly appreciated!”